Menu

Open

Close

The Pininfarina-styled MGB was the ubiquitous British sportscar. Over half a million were built from 1962-80 and, although designed to a low budget and built to a questionable quality standard, every one of them brought glamour, practicality and joy to its enthusiastic owner.

MGBs were also easy to work on, and even today officially sanctioned original machinery reproduces original body shells. So, the market was strong for a much-improved MGB: for the kind of car the MG engineers originally dreamed of building, before the money men got involved... And Tim Fenna took on the challenge, creating one of the very first 'restomod' classic cars: that is a much improved and thoroughly modernised version of an existing classic car.

While other 'restomod' firms took high quality, exotic cars as the 'basis' vehicles - Porsches, E-type Jaguars, Mercedes - Tim was determined to evolve the MGB into something world beating. It was light, popular, pretty and the basic design was terrific. And there were modern engines from Mazda that suited the vision perfectly...

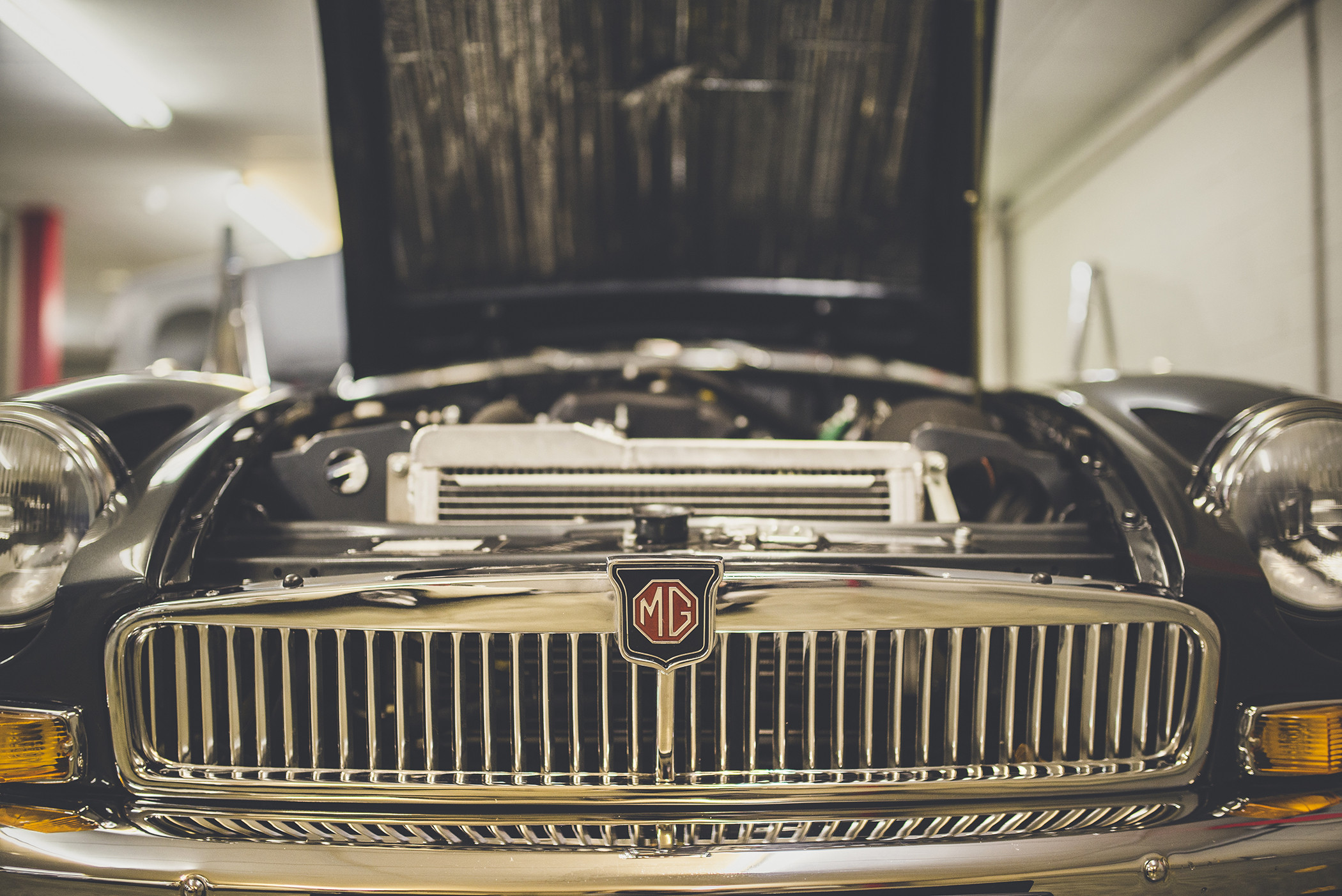

So, Frontline MGs were to be far more than dressed-up or accessorised 'restomods': they were to rebuilt to ultimate standards, from all aspects of the engineering (drivetrain, suspension, brakes, rigidity) to door shut-lines, panel seams and every detail. Taking a lead from the finest custom and coachbuilding traditions and combining them with cutting-edge race-bred engineering, the result is a Frontline MG: high performance cars like no others in the world.

There is probably no other company that takes a 50-60 year old low-cost, mass-produced sports car and turns out into a model the fits perfectly into the modern world. Moreover, a car that is an icon and heirloom - something to treasure forever.

As any classic car owner knows, modern cars are built to far better standards and impressive levels of efficiency and reliability. However, modern cars are also often very boring indeed.

At Frontline, the charisma and appeal of the original MGB is fundamentally imbued into the brilliance of the modernised tech. Moreover, all the rough edges and compromises are painstakingly removed. Even the paintwork is several times as thick, and takes hundreds of hours to perfect. And the interior is more akin to a fine glove than sports car vinyl of old…

Above all, it’s a very personal process. The customer is involved at every stage from conception and commission to creation and refining: it’s a happy and rewarding journey in the making.